Ensure Steady Power with Static Voltage Stabilizers: Uninterrupted Performance in Every Voltage Fluctuation!

Robust Solutions for Uninterrupted Operations. Unleash the Power to Overcome Sags and Dips: Stay Connected and Productive!

Optimize Power Quality with Active Dynamic VAR Compensators: Keep Your Voltage Stable and Efficiency High!

Today, electricity is one of the main raw materials used by industry.

The energy produced in power stations is distributed to consumers through the transmission and distribution networks. The quality of the electricity, universally defined as power quality, is one of the factors that determine the economic efficiency both of the consumer systems and electrical networks.

CONCERN / ISSUES

Electrical equipment is designed to function in power supply systems considered by rated voltage values (e.g. 400V) and frequency values (e.g. 50Hz).

Actually, the distribution of electricity can be such that it does not ensure the constancy of these parameters. In particular, the supply voltage may go through variations, even significant ones, compared to the rated value that may cause undesired conditions that are possibly very damaging for users.

These voltage variations may be “fast” and end in just a few milliseconds (for example, as a result of lightning hitting the lines) or “slow”, lasting several seconds, minutes, or even hours, depending on the cause. The “slow” variations may be triggered by poor MV regulation by the power distributor, detachment of large loads from the mains, output overvoltage from generators, etc. and, more frequently, by drops due to connection of large loads, starting up of big size motors, undersized power lines and ground faults.

The static voltage stabilizer is the solution that ensures the best cost/benefit ratio for voltage variations. The continuous availability of steadily supplied voltage, free of input fluctuations, is the key for ensuring efficiency and reliability for the final user.

Reduced productivity, data loss, equipment failures are just some examples of potential issues caused by unstable supply. All this transforms into an increase production cost of the manufacturing industry.

SOLUTION

The static voltage stabilizer is an effective solution for preventing potentially damaging situations caused by input voltage instability.

Compared with other types of equipment, the voltage stabilizer has a series of advantages that often make it the optimal solution. The cost is generally lower and provides the following benefits:

The voltage stabilizer works without batteries.

The voltage stabilizers are simple to use, have a very high yield, are small in size, and have a reduced sensitivity to inrush currents.

The standard three-phase models can operate with a rated voltage of 380V-400V-415V (50Hz).

The standard three-phase voltage stabilizers have independent phase control. The stabilizer must be connected to the neutral of the power line.

This is an important piece of data for choosing and sizing the stabilizer. The amount of input voltage variation needs to be identified, keeping a safety margin. For example, voltage variations of ±16% on the rated voltage are measured, a stabilizer sized for ±20% variations should be chosen. Attention to the following rule: if the input variation exceeds the pre-established one, the difference in excess is added to the output precision. For example, if a stabilizer sized for ±15% receives a variation of +20%, the precision of the output voltage will no longer be ±0.5% but ±5.5%.

The voltage is not ever perfect!

Temporary reduction of the rated voltage below a specific threshold at one point of the electricity supply line.

A voltage sag occurs when the residual voltage is reduced to values ranging between 90 and 10 per cent of the rated voltage. The length of the voltage sag is considered between 10 ms up to 1 minute. The majority of voltage sags lasts less than 1 second and has a residual voltage greater than 40% of the rated voltage.

If the quality of the electricity goes below a certain level, the equipment no longer operates correctly and issues will probably occur. The total incidence of these costs can be quantified up to 4% of the company’s annual turnover, with peaks around 60% caused by voltage sags (SAG) and short interruptions.

The impact of a voltage sag on the production process is definitely lower than that of an interruption, but it should be considered that voltage sags are much more frequent. The interruption hits all the equipment not protected by UPS, while a voltage sag, depending on its depth and duration, may have the same effect or only affect the most sensitive appliances.

SOLUTION

In manufacturing industries, the production process can be optimized with voltage stabilization and voltage sag compensation. The Dynamic Voltage Stabilizer provides most suitable solution against SAGS / DIPS.

Most of the loads in the power grid and industries are inductive loads, such as motors, transformers, etc. At run time, the power grid needs to deliver reactive power to these devices. The reactive power compensation equipment is installed in the power grid, so that the reactive power required for inductive load can be compensated from the reactive power compensation equipment, and the power of the grid transmission is saved. It is the basic principle of reactive power compensation.

At present, the conventional reactive power compensation equipment uses the contactor or thyristor to switch the capacitor and reactor to compensate the reactive power, to improve the power factor of the system. However, this approach cannot keep up with the rapid changes of load.

At the same time, because the capacity of each group of capacitors is fixed, the reactive power compensation capacity can only be switched in steps, and the compensation accuracy is poor. A better compensation results cannot be provided. The new static VAR generator (SVG/STATCOM) has gradually entered the field of reactive power compensation. Based on the principle of the voltage source inverter, the power semiconductor (IGBT) is used in SVG to control the amplitude and phase of the inverter AC voltage, to achieve the purpose of reactive power compensation. The SVG can quickly compensate for inductive or capacitive reactive loads, and the power factor can be compensated to 0.99 or greater accuracy. Because of its different working principle with capacitor compensation, there is no overload, over compensation, under compensation, and harmonic amplification.

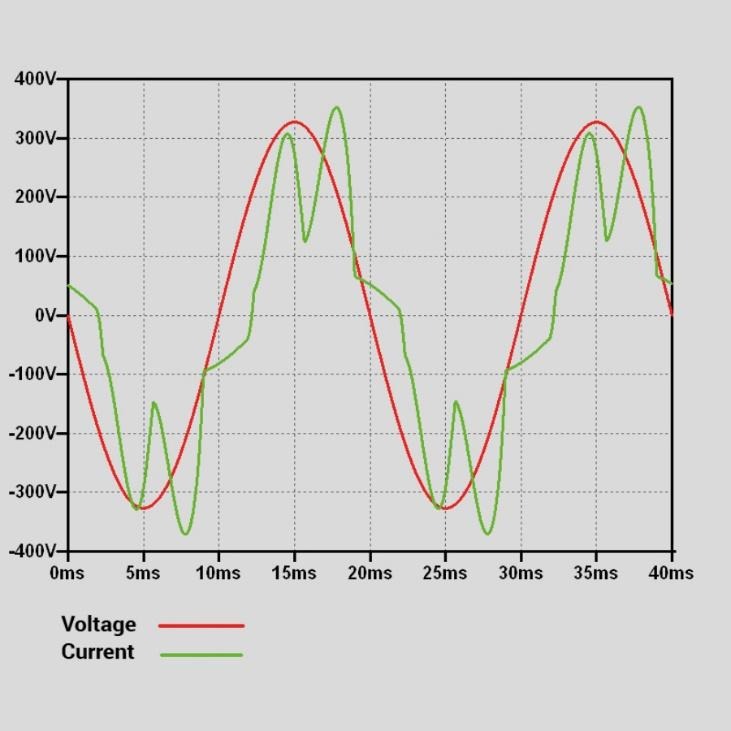

In industrial and service sector electrical plants, there are many non-linear appliances: inverters, soft starters, rectifiers, power electronics, presses and furnaces. When there is a nonlinear load in the power system, a voltage or current waveform deformation is generated with the other frequency components, different from fundamental frequency (50Hz).

The distortion components in voltage or current are known as harmonics.

In industrial and service sector electrical plants, there are many non-linear appliances: inverters, soft starters, rectifiers, welders, power electronics, non filament lighting, presses, furnaces, etc.

These cause the deformation of the current with resulting disturbances and problems for the plant, i.e.:

At present, the conventional reactive power compensation equipment uses the contactor or thyristor to switch the capacitor and reactor to compensate the reactive power, to improve the power factor of the system. However, this approach cannot keep up with the rapid changes of load.

At the same time, because the capacity of each group of capacitors is fixed, the reactive power compensation capacity can only be switched in steps, and the compensation accuracy is poor. A better compensation results cannot be provided. The new static VAR generator (SVG/STATCOM) has gradually entered the field of reactive power compensation. Based on the principle of the voltage source inverter, the power semiconductor (IGBT) is used in SVG to control the amplitude and phase of the inverter AC voltage, to achieve the purpose of reactive power compensation. The SVG can quickly compensate for inductive or capacitive reactive loads, and the power factor can be compensated to 0.99 or greater accuracy. Because of its different working principle with capacitor compensation, there is no overload, over compensation, under compensation, and harmonic amplification.

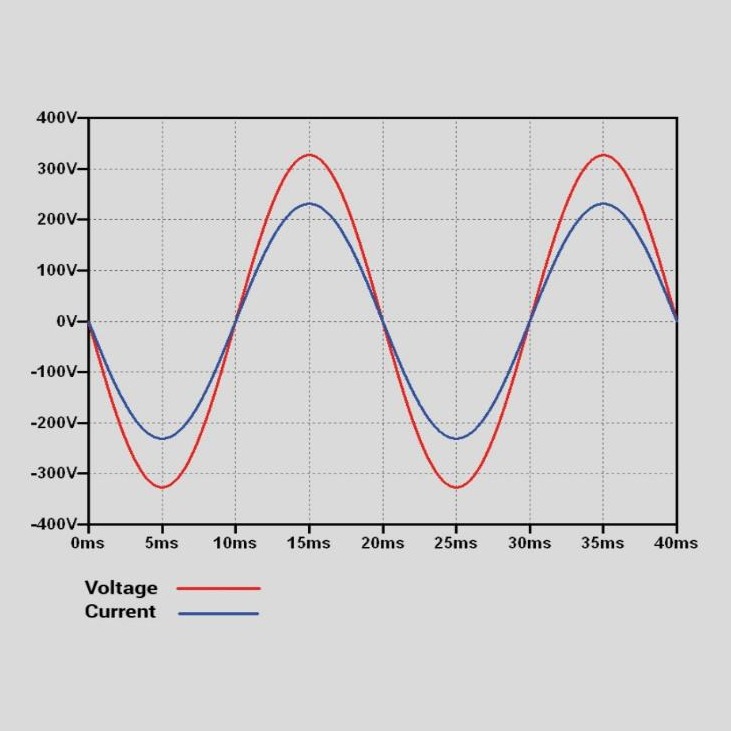

Active harmonic filter drastically reduce the current and voltage distortion and problems with the most sensitive appliances are eliminated. These filters cancel the harmonic distortions in the plant’s current, first measuring them and then injecting the same currents but in inverted phase. In this way, a sinusoidal current is delivered to the appliances with excellent power quality.

Example of non-linear load harmonic distortions

The harmonic distortions are compensated

Backup power solution (UPS)with high solution high operation efficiency of 97% & 2ms switching